Small step forward to bring us closer to sustainable solutions for people and the planet.

We are dedicated to creating cleaner, smarter communities through lasting innovation. Just as water persistently shapes stone, our approach unites modern technology with environmental responsibility—progressing steadily, thoughtfully, and without compromise to people or nature. We focus on practical, forward-looking solutions that everyone can take part in and benefit from.

Reclaiming coal tailings lakes is an essential step in restoring ecosystems impacted by mining activity. These lakes, often left with high levels of sediment and residual contaminants, pose long-term environmental challenges if unmanaged. Through careful treatment, sediment stabilization, and the introduction of clean water and vegetation, reclamation transforms these sites from industrial byproducts into safe, sustainable landscapes. The process not only reduces risks to surrounding communities and wildlife but also creates opportunities for land reuse, water recovery, and ecological renewal.

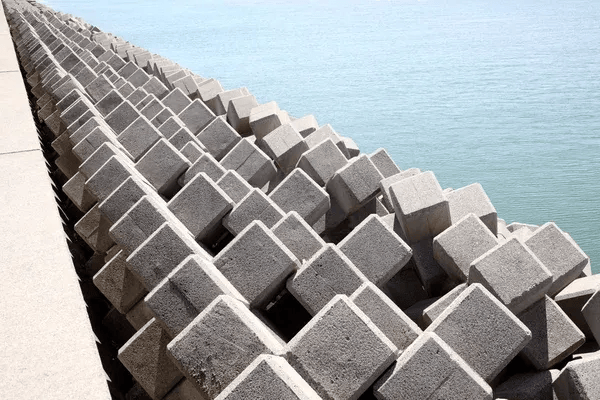

The remediation of dredged sediment into construction blocks represents an innovative approach to both waste management and sustainable development. By stabilizing and treating contaminated or excess sediments, harmful components are neutralized, and the material can be transformed into durable, reclaimed building blocks. These blocks can be used in a wide range of applications, including the construction of seawalls and shoreline protection systems, where strength and resilience are essential. This process not only diverts large volumes of dredged material from landfills but also reduces the demand for virgin resources in construction. The resulting blocks provide a practical, eco-friendly alternative for infrastructure and coastal defense projects, turning an environmental liability into a valuable resource.

The conversion of coal into synthetic crude oil represents a pathway to remediate coal resources while generating a usable energy product. Through advanced liquefaction technologies, coal’s solid carbon structure is broken down into liquid hydrocarbons that can be refined into fuels or chemical feedstocks. By integrating recycled plastics into this process, additional hydrocarbon value can be recovered, reducing plastic waste while improving overall efficiency. This approach not only lessens the environmental footprint of coal and plastic waste but also provides an opportunity to recover energy value from resources often considered outdated or harmful. When paired with carbon capture and cleaner production methods, coal-to-crude remediation can serve as a transitional technology, balancing current energy demands with the move toward more sustainable solutions.

Want to learn more or explore working together? Let’s start the conversation.